Consistency in day-to-day business

As we repair fittings and components from a wide range of manufacturers ourselves, we know their specific properties inside out.

In the event of malfunctions, it is therefore worth having us check first whether a repair might be more sensible from a functional and economic point of view than a simple replacement.

” In many cases, we can help to reduce our customers’ operating costs many times over. “

What we can repair...

Everything from a single source – across manufacturers

During our repairs, all actuators are refurbished and tested to the highest standard in accordance with the manufacturer’s specifications. Only original spare parts are used.

- Control valves/shut-off valves

- Ball and plug valves

- Flaps, sliders

- Rotary plug valves / ball sector valves

- Pressure reducer

- Overflow

- Actuating cylinder

- Pneumatic actuators

- Safety valves

- Electric drives

This is exactly where the first roots of Mach GmbH lie, when the founder Martin Mach Sr. started in 1977 to repair pressure gauges and positioners for BASF in Ludwigshafen as one of the pioneers in outsourcing. To this day, this customer, who is known for the highest standards in these areas, has remained with us in this and other new sectors.

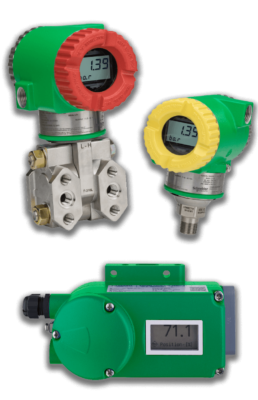

- Transmitters for: Pressure, level, flow, pneumatic devices

- Pressure gauge

- Positioner

- Pneumatic drives

- Electric drives

Investment revisions

Reliable service center for system overhauls: Planning, repair, commissioning, certified quality and original spare parts.

One of our main focuses is to support our customers with system overhauls through our service center. Fittings and equipment from various manufacturers in a wide range of variants have to be checked and overhauled within a fixed period of time. We are a reliable and experienced partner from the planning and implementation of repair measures through to commissioning. Whether control valves, manual valves, measurement technology or safety valves, we restore your field devices to perfect and as-new condition. As a direct service partner of some valve manufacturers as well as of Groß-Chemie, we work to the highest standards and, of course, only use original spare parts recommended by the manufacturer. Our specially designed clean room, approved by BASF in accordance with CIS specifications, enables us to handle even toxically contaminated equipment in an environmentally friendly and safe manner.

The processing of safety valves has been one of our core maintenance activities for more than 25 years now. All final inspections are carried out and certified in our company by SGS-TÜV Saar GmbH or TÜV Rheinland. Our professional machining center and the necessary testing equipment guarantee the highest quality and therefore safety.

AUTHORIZED SERVICE

Excellence in every sector: put your trust in our expertise

We are an authorized service partner for manufacturers such as Schneider Electric, FlowServe and Valmet.

We can also offer you the service for the following manufacturers: Schmidt-Armaturen + Kämmer valves, Klinger Schöneberg ball valves, Garlock PTFE butterfly valves, Vetec valves, SAMSON (BASF) authorized, Somas, Ramén Valves and others. For our major customers in particular, we work closely with the respective manufacturers. This takes place in our factory in Enkenbach-Alsenborn or directly in your plant.

Of course, our customer service also looks after a wide range of products from other brands. This means that you only have one point of contact, regardless of where the devices and elements to be serviced come from.

Your system in the best hands - reliability through experience

During a system overhaul, we take care of all the necessary maintenance work for you and ensure that your company can resume operations on time. So you can concentrate on your core competencies and leave the rest to us.

Everything from a single source – across manufacturers